Electroless Plating/Electrolytic Plating Equipment for Printed Circuit Boards (PCB)

Product Lines for Electrolytic and Electroless Plating

Explore our range of Electrolytic and Electroless Plating equipment, each designed and built to accommodate your specific process. When you are ready, contact our expert team to design the solution you need.

What Industries use Chemcut Electroless and Electrolytic Platers?

Our electroless and electrolytic platers are designed for the PCB fabrication industry. Since our equipment is designed for flexibility and customization, it makes our machines a great solution for any plating or wet processing project.

Most our plating projects are conveyorized plating, so they can be integrated into a conveyorized PCB fabrication process.

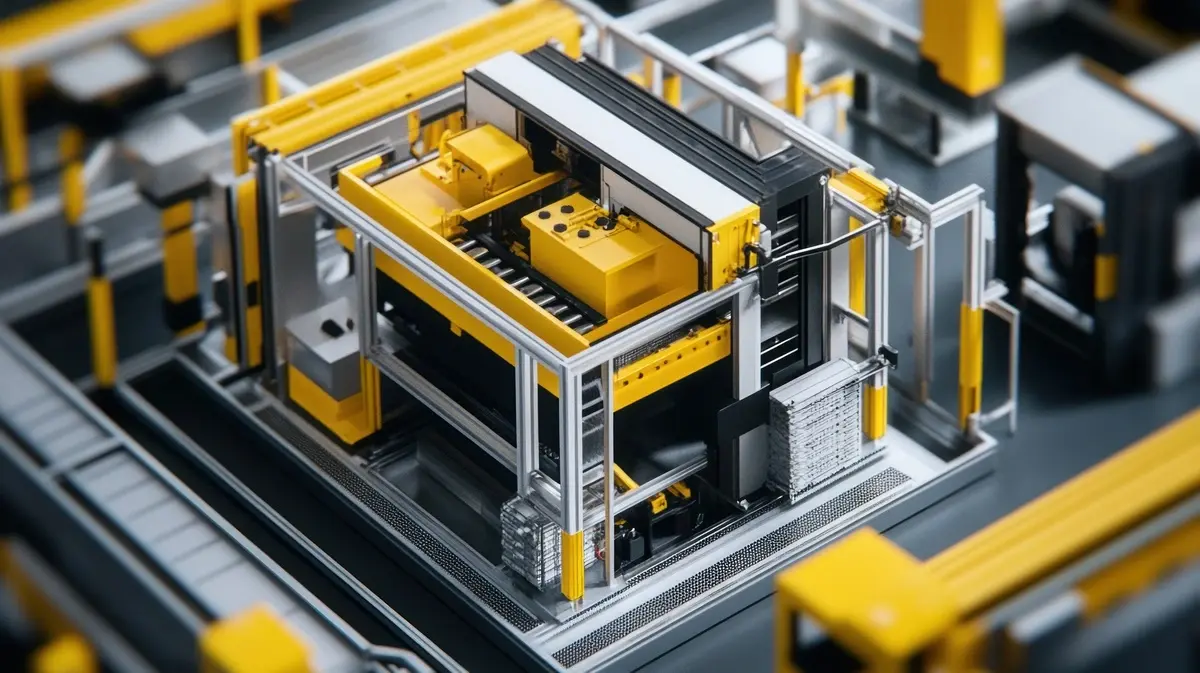

990D Electroless Plating System

Product Lines for Electrolytic and Electroless Plating: CC8000, Dip Tanks, XLi, 2300 Series

- Desmear

- Electroless Copper Plating

- Electroless Nickel Plating

- Electrolytic Copper Plating

- Electrolytic Gold Plating

- Electrolytic Silver Plating

- Electrolytic Tin Plating

- Immersion Gold Plating

- Immersion Silver Plating

- Immersion Tin Plating

- Ni/Au Plating

- PTH (Plated through-hole) Any discussion on this topic should include your chemistry supplier as well. It is critical that the bath for PTH is monitored closely.

- Inner layer bonding operations: brown oxide (Bondfilm, Multibond, etc.), (white ‘oxide’ – immersion Tin)

Ion Exchange System

- Closed-loop system

- Decrease your water usage by connecting an ion exchange to your rinse water

What Plating Systems Do We Offer?

We can help you design and build your plating line to support Printed Circuit Board manufacturing (PCB).

Horizontally conveyorized plating systems are available for desmear, activation, and electroless copper plating processes, including plated through holes (PTH). Other supported plating processes include electroless nickel plating, immersion tin process, immersion silver process, and immersion gold.

Vertical plating lines are available for electroless plating of copper, electroless plating of nickel, electrolytic copper, electrolytic tin, electrolytic silver, and electrolytic gold.

Chemcut will build systems that incorporate electroless plating as needed (horizontal). For electroless processes, a supplier’s chemistry can be tested in one of our smaller spray tools, the 2300 series.

Construction in CPVC and PP is available for use, and testing in immersion chemistry can also be done in our research and development lab. For actual plate up and metallic resist plating, electrolytic is done on a vertical line with a hoist that can be programmed for semi-auto operation.

Related Resources

Optimize a Wet Processing for Design & Spacing

Effective space planning and design are critical to the success of wet processing facilities....

How to Scale Up Manufacturing | Strategies to Improve Efficiency & Reduce Costs

Scaling up manufacturing presents both challenges and opportunities for engineers who must...

How to Scale Up Production with Chemical Milling & Etching

Chemical milling and etching are powerful techniques widely used in industries requiring precise,...

High quality products are made with high quality equipment. Stake your reputation on Chemcut.

Already a customer?

Chemcut’s commitment to you goes beyond the sale. We keep your equipment running with the industry’s best post-sales support, which includes our in-house R&D lab and global field service assistance.

We also maintain the industry’s largest and most diverse inventory of high-quality replacement parts to ensure prompt delivery regardless of the type or age of your Chemcut or MEI Division equipment.