Chemical Etching Equipment

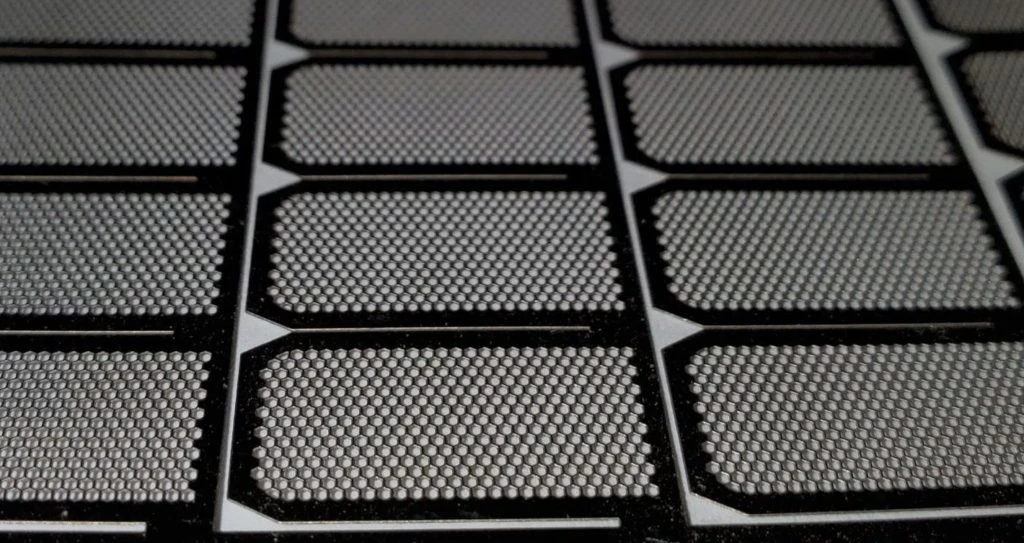

Chemical Etching for Printed Circuit Boards (PCB), Chemical Machining, and Much More.

Product Lines for Metal

Explore our diverse range of chemical etching product lines, each readily tailored to suit your specific process. When you are ready, contact our expert team to design the solution you need.

XLi Etching Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

XLi with External Automatic Pressure Adjust

Control the spray pressure of each spray tube using the PLC instead of the throttling screw.

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

2300 Series Etching System

- 15″

- 20″

- 30″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

2800 Drawer Etcher

- An adjustable drawer type rack

- Loads parts horizontally up to size 21″ x 21″

- Oscillating spray tubes

- Oscillating rack to maximize etchant movement

CC8000 Etching Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

Etch Adjust Module (EAM)

- CC8000 Etching Systems

- XLi Etching Systems

- Plated boards: Correct side to side etch difference when one side is plated more

- Fine-tune very small features

Ion Exchange System

- Closed-loop system

- Decrease your water usage by connecting an ion exchange to your rinse water

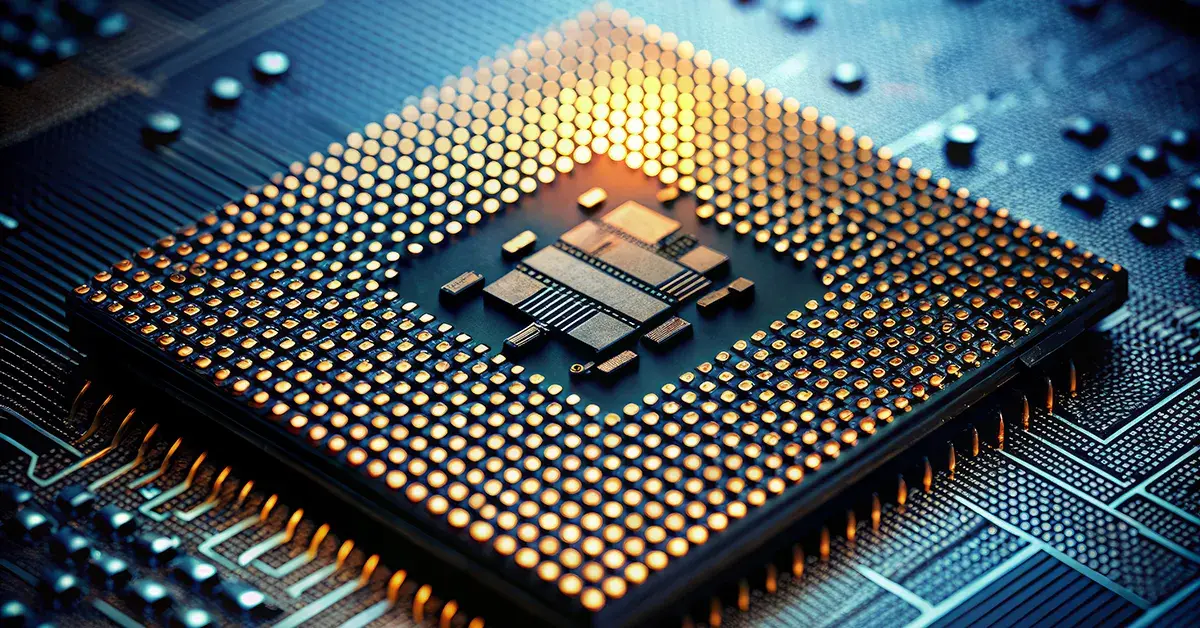

Common Acids Used for Engraving Metal and Glass

- Alkaline (printed circuit board etcher)

- Etch Machine for PCB

- Cupric Chloride (printed circuit board fabrication)

- Etch Machine for PCB

- Ferric Chloride (Photo etching process and printed circuit board etcher)

- Stainless Steel etching

- PCB manufacturing

- Specialty metal etchant (list of specialty metals)

- Hydrofluoric Acid (chemical milling and glass etching)

- Titanium etcher

- Molybdenum etcher

- More specialty metal etchers

- Other uses for Chemcut etchers

- Custom semiconductor processing

- Etcher for proprietary processes

Benefits of a Chemical Etching Process

Accurate and Complex

Metal etching ideal for making extremely complex designs and accurate metal components. Since all the features are being machined at the same time, the complexity can be endless.

Bur Free and Stress Free

Since the etching process is chemical machining instead of mechanical machining, the components will be bur free, stress-free, and will maintain all their original metal properties.

Fast Prototyping and Quick Design Changes

The digital tooling process in metal etching enables etcher owners to modify component designs swiftly and easily.

Endless Metal Options

Check out our Chemical Milling page to view a list of metals for which Chemcut etchers have already been developed.

Common Line Parameters

Speed range: 14 – 140 inches / minute

Max temperature: 130 °F

Processes will vary depending on metal, etchant, and desired properties of product.

Why should your business add chemical etching to your list of capabilities?

No Stress Hardening

Burr Free

Stamping produces parts with sharp edges, requiring removal for safe handling.

Unlimited Complexity

Typically, chemical milling companies charge for the first hole.

Quick Turn Around on Redesigns

Chemical etching is ideal for producing multiple prototype designs with minimal downtime.

Quick and Economical Prototyping

The artwork is inexpensive.

No Expensive Hard Tooling Like Stamping

Etched Parts Are NOT Compromised by Contamination.

Many parts are used in the medical field.

Nearly Any Metal Can Be Etched in a Chemcut Machine.

Acid Etching Metal on a Chemcut Machine Can Have a Tolerance of 10% of the Material Thickness

Even better with artwork compensation prior to resist exposure.

Tolerance of 1 Mil and Lower is Achieved by Many of Our Customers.

Related Resources

Optimize a Wet Processing for Design & Spacing

Effective space planning and design are critical to the success of wet processing facilities....

How to Scale Up Manufacturing | Strategies to Improve Efficiency & Reduce Costs

Scaling up manufacturing presents both challenges and opportunities for engineers who must...

How to Scale Up Production with Chemical Milling & Etching

Chemical milling and etching are powerful techniques widely used in industries requiring precise,...

High quality products are made with high quality equipment. Stake your reputation on Chemcut.

Already a customer?

Chemcut’s commitment to you goes beyond the sale. We keep your equipment running with the industry’s best post-sales support, which includes our in-house R&D lab and global field service assistance.

We also maintain the industry’s largest and most diverse inventory of high-quality replacement parts to ensure prompt delivery regardless of the type or age of your Chemcut or MEI Division equipment.